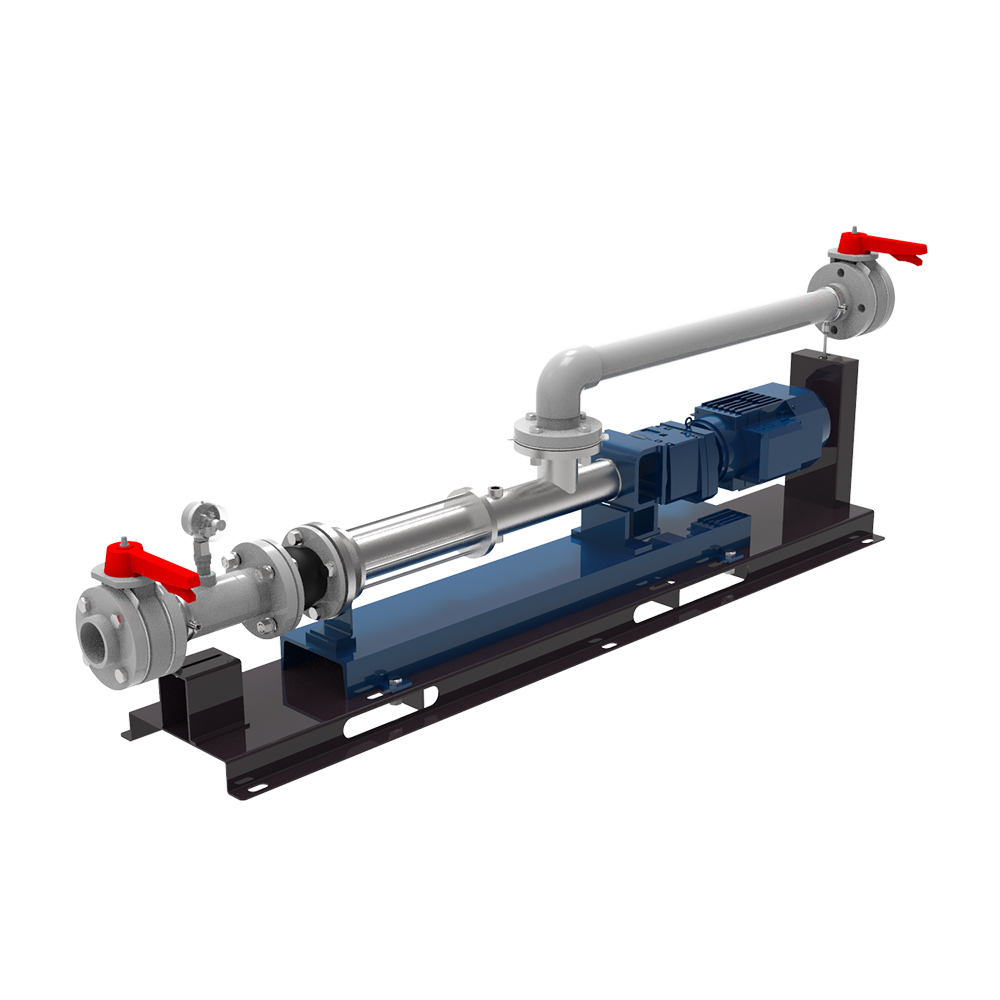

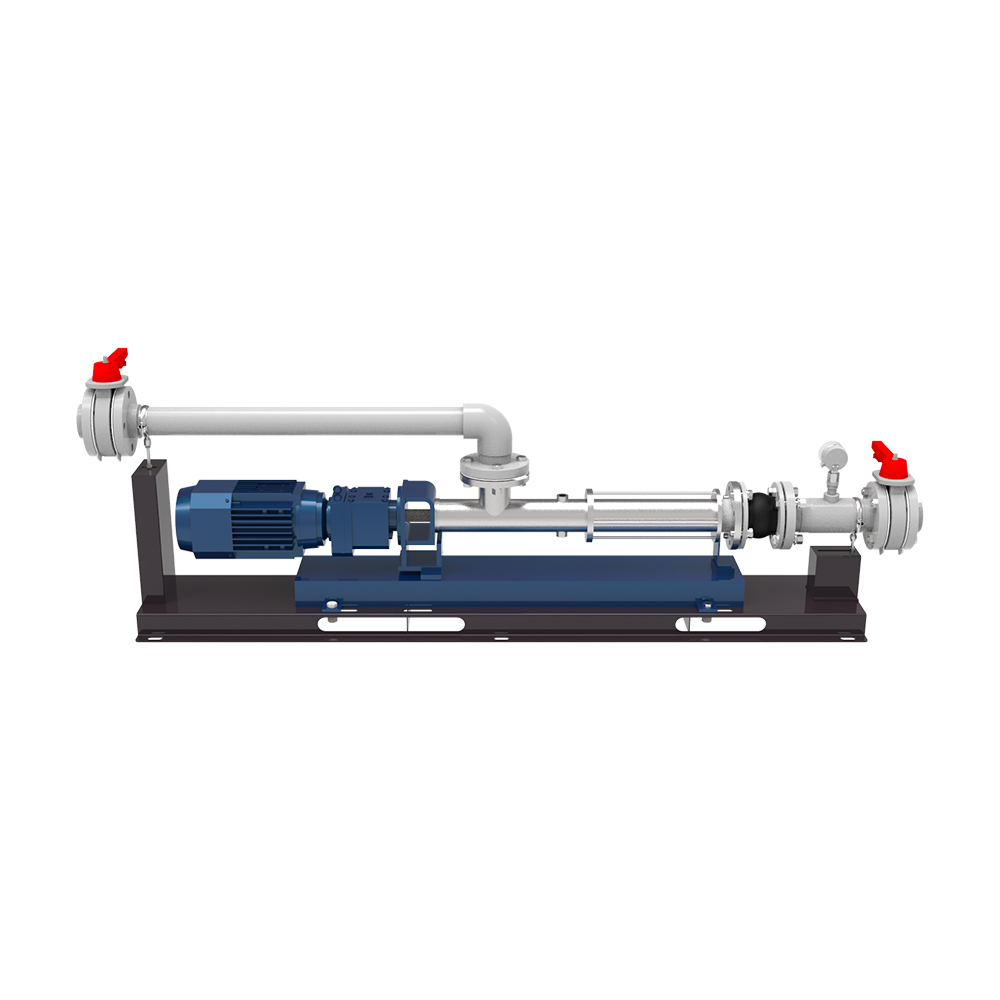

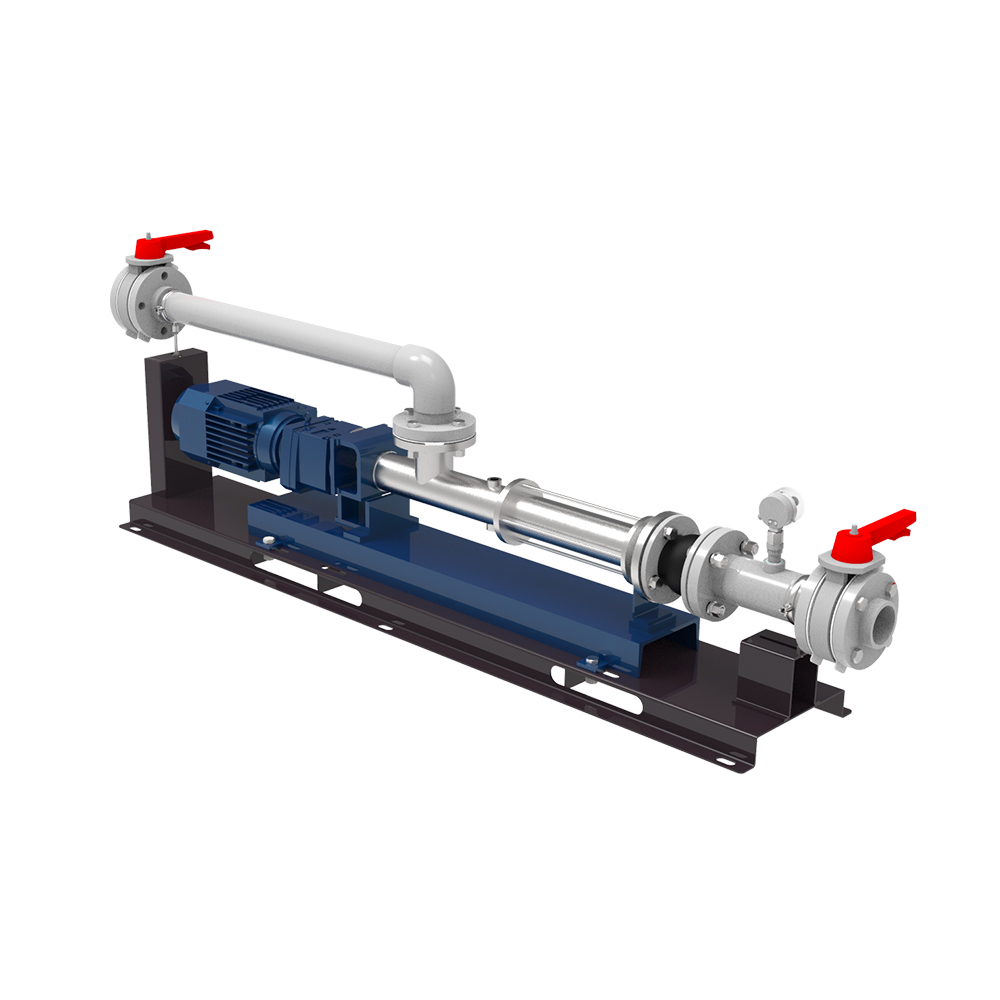

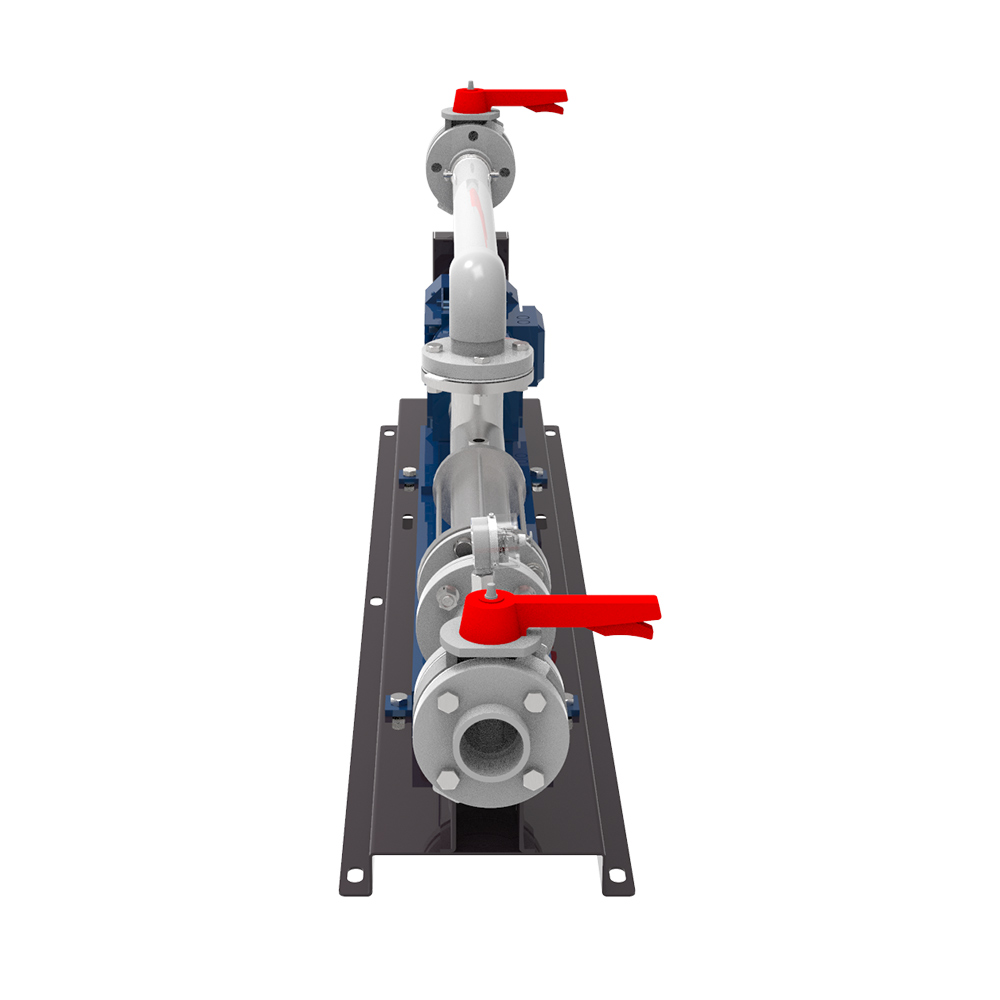

VD035-P04OH-S-JRTRF39DN100L4

Screw pumps are specifically engineered to handle fluids that are abrasive, viscous, or shear-sensitive, where steady, non-pulsating flow is essential. They are commonly used in chemical transfer, oil and lubricant distribution, sludge handling in wastewater plants, and additive dosing in new energy manufacturing, such as copper foil production for electric vehicles (EVs). Their unique design ensures minimal turbulence, which is crucial for preventing damage to sensitive materials like emulsions, food products, or bio-materials.

Screw pumps operate by using one or more intermeshing screw rotors to move fluid along the pump chamber. As the screws rotate, fluid is drawn in from the inlet side and transported steadily to the outlet. Unlike centrifugal pumps, screw pumps maintain a consistent flow regardless of pressure fluctuations, making them particularly valuable for applications where precision and stability are critical. These pumps can handle both low-viscosity fluids like water, fuels, and solvents, and high-viscosity media such as oils, greases, sludges, and polymers. Their ability to work under low shear and minimal turbulence makes them ideal for transferring sensitive or foaming-prone liquids.

Product Advantages

1. Pulsation-Free Flow

The unique screw configuration ensures continuous, smooth flow without the pulsation common in other positive displacement pumps. This reduces vibration, noise, and stress on downstream equipment.

2. Wide Viscosity Range

Variable Speed Screw pumps are highly versatile and can handle everything from thin, low-viscosity fluids to thick, viscous materials without compromising flow rate or pump integrity.

3. Pressure-Independent Operation

These pumps maintain steady performance even when discharge pressure fluctuates, making them ideal for processes with variable system resistance.

4. Gentle Fluid Handling

Low shear and minimal turbulence make screw pumps ideal for shear-sensitive liquids like emulsions, food products, or bio-materials. This also helps prevent foaming and degradation.

5. Self-Priming and Excellent Suction

Thanks to their positive displacement nature, screw pumps are capable of self-priming and delivering reliable suction lift, even with difficult or viscous fluids.

6. Durable and Corrosion-Resistant Construction

Manufactured with precision-machined components and materials like stainless steel, screw pumps offer excellent resistance to wear, corrosion, and chemical attack.

7. Low Noise and Low Maintenance

Quiet operation and a simple mechanical structure lead to minimal maintenance requirements and reduced downtime.

8. Modular and Customizable Design

Screw pumps can be tailored to specific flow rates, pressure ranges, or fluid characteristics. This makes them suitable for specialized applications or integration into complex systems.

Product Applications

Screw pumps are highly adaptable and can be used across a wide range of industries, particularly for applications involving viscous, abrasive, or corrosive fluids. Below are some of the key sectors where screw pumps are used to meet demanding operational requirements:

1. Sewage Treatment (Water and Wastewater Treatment)

Screw pumps are crucial in wastewater treatment plants for transferring sludge, slurry, and chemical additives. In the sewage treatment process, they handle highly abrasive and viscous materials such as sewage sludge, which must be processed and treated for safe disposal or reuse. Due to their self-priming nature and ability to work with thick, gritty slurries, screw pumps ensure smooth, pulsation-free operation, helping to maintain a steady flow and prevent blockages in the system.

Application: Transporting sludge and dosing chemicals like flocculants or pH adjusters.

Benefit: Smooth, continuous flow with minimal wear on parts, ensuring long-term reliability and low maintenance.

2. Automobile Manufacturing

In automobile manufacturing, screw pumps are used for a variety of tasks, including the transfer of lubricants, oils, and paint additives. A key application is in the paint color mixing and masterbatch feeding, where precise and consistent dosing of colorants and other additives is essential to maintain the quality of the finish. The pumps' ability to handle viscous liquids and provide stable flow under varying pressure makes them ideal for the controlled addition of paint components in high-volume operations.

Application: Dosing masterbatches, paint additives, and lubricants in the manufacturing process.

Benefit: Consistent, accurate transfer with minimal turbulence, preventing damage to shear-sensitive components like paint.

3. New Energy (Copper Foil Manufacturing Additives)

In the new energy sector, particularly for copper foil manufacturing, screw pumps are used to dose additives precisely into the production line. Copper foil is a key component in batteries for electric vehicles (EVs) and energy storage systems, and the manufacturing process requires the addition of specific chemicals to control thickness, uniformity, and quality. The screw pump’s accurate and steady dosing is crucial for maintaining the high standards required in battery production.

Application: Dosing additives in copper foil manufacturing, including chemical agents for thickness control.

Benefit: High precision and minimal shear damage to delicate additives.

Screw pumps combine robust performance with gentle, efficient fluid handling, making them one of the most versatile pumping solutions available today. Their ability to handle a broad spectrum of fluid types—regardless of viscosity or abrasiveness—along with their smooth flow characteristics and energy efficiency, makes them ideal for continuous-duty applications across a wide range of industries. Whether for complex process systems or standalone operations, a screw pump delivers reliability, precision, and long-term value.