NM021BY01L06B-A00262-L

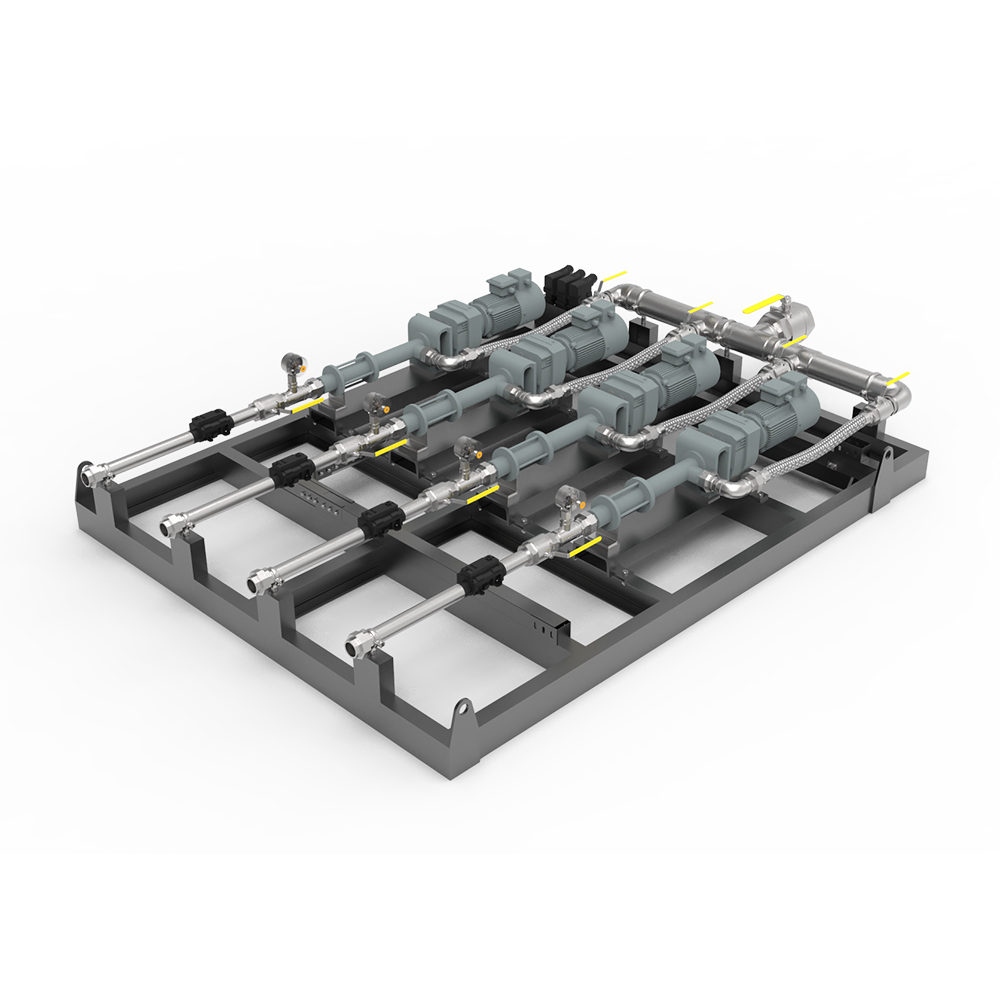

Screw pumps are efficient and versatile solutions for handling viscous, abrasive, and shear-sensitive fluids. Their steady, non-pulsating flow makes them suitable for applications requiring precision and consistency, such as chemical transfer, lubrication systems, and wastewater treatment involving sludge or slurry.With direct-drive or gear-driven designs, screw pumps deliver smooth, low-noise operation, strong suction, and reliable performance under varying pressures and viscosities, reducing maintenance needs.

Screw pumps operate using one or more intermeshing screw rotors that transport fluid along the pump chamber. As the screws rotate, fluid is drawn in through the inlet and smoothly displaced to the outlet. This low-shear process minimizes turbulence, foaming, and mechanical wear, which is especially beneficial for applications requiring gentle fluid handling.

With either direct-drive or gear-driven mechanisms, screw pumps are capable of maintaining consistent flow even under fluctuating pressure conditions. Their self-priming ability and strong suction characteristics also enable them to handle thick or particle-laden fluids with ease, making them suitable for complex dosing and transfer operations.

Key Advantages

1. Pulsation-Free, Steady Flow

Industrial Screw Pumps ensure a continuous, smooth flow of fluid without the pulsation found in other positive displacement pumps. This makes them ideal for precision dosing or blending applications, where uniform delivery is essential.

2. Wide Viscosity and Fluid Compatibility

From light solvents to dense sludges, screw pumps excel across a broad viscosity range. They handle abrasive or corrosive media and are suitable for fluids with solid content, ensuring versatility in application.

3. Energy Efficiency and Low Noise

Thanks to their streamlined internal geometry and stable operation, screw pumps offer excellent volumetric efficiency while operating quietly. This helps reduce energy consumption and noise in sensitive environments.

4. Gentle Fluid Handling

The screw mechanism creates minimal shear and turbulence, which protects fluid integrity and prevents foaming or breakdown—critical in processes involving emulsions, polymers, or enzyme solutions.

5. Long Service Life and Low Maintenance

Constructed with corrosion-resistant materials and a simple mechanical structure, screw pumps are highly durable and require minimal maintenance. This leads to reduced downtime and lower operational costs over time.

Applications in Key Industries

1. New Energy: Copper Foil Manufacturing Additive Dosing

In the production of battery-grade copper foil, precise chemical dosing is critical to control thickness, texture, and conductivity. Screw pumps enable accurate, pulsation-free delivery of additives like brighteners or leveling agents into the electroplating process. Their compatibility with aggressive chemicals and consistent dosing performance make them indispensable in new energy material manufacturing.

2. Water and Wastewater Treatment: Chemical Dosing

In municipal and industrial water treatment plants, screw pumps are used to deliver pH adjusters, flocculants, and other chemical agents. Their ability to handle corrosive, abrasive, and high-viscosity liquids—such as sludge conditioners or neutralizing agents—ensures optimal dosing performance and long-term reliability.

3. Bio-Energy: Enzyme Additive Injection

Bio-energy systems, such as anaerobic digesters, require precise dosing of enzymes and nutrients to optimize microbial activity and gas yield. Screw pumps provide stable, low-shear injection of sensitive bio-additives, helping maintain biological balance and enhance efficiency in biogas or bioethanol production.

4. Metallurgy and Chemicals: Acid Dosing in Smelting

Screw pumps are ideal for transporting acid additives such as sulfuric, hydrochloric, or nitric acid in metal refining processes. Their corrosion-resistant build and reliable flow control ensure safety and efficiency when dosing aggressive or volatile chemicals in metallurgy and chemical production.

Screw pumps are a high-performance solution for fluid transfer challenges across diverse industrial sectors. Their ability to handle a wide range of fluid types—regardless of viscosity, abrasiveness, or sensitivity—combined with low-maintenance operation, high efficiency, and customizable configurations, makes them an invaluable tool in modern process systems.

Whether you're optimizing chemical dosing in wastewater treatment, ensuring quality in new energy manufacturing, or maintaining smooth operations in metal processing or automotive production, screw pumps deliver reliable performance, long-term durability, and peace of mind.