E01A 090-03 M1

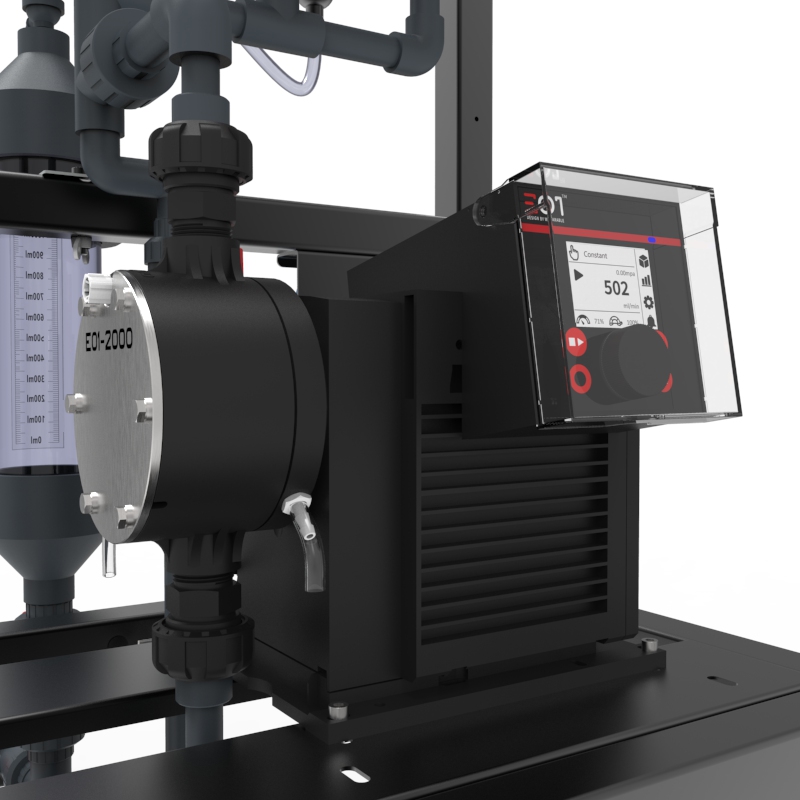

Digital dosing pump systems with intelligent control modules deliver precise chemical dosing across a wide range of applications. The product line spans compact high-accuracy units to advanced models with digital interfaces, suitable for water treatment, new energy, metallurgy, and laboratory use. Designed for stable, pulse-free flow, these pumps support flexible programming, flow-proportional dosing, batch control, and seamless integration into automated systems.

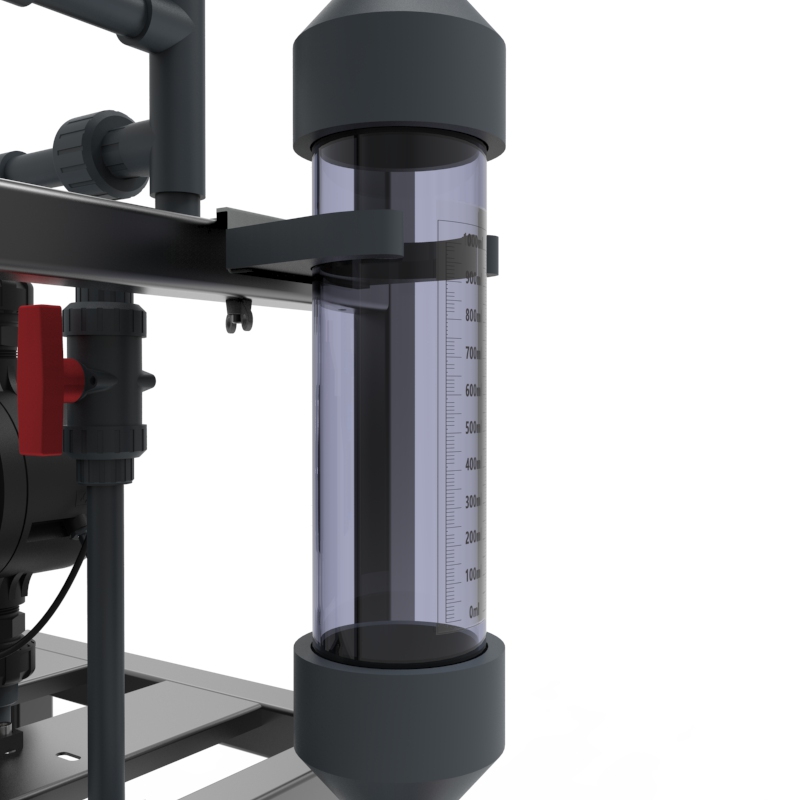

Dosing pump system is built to deliver small, controlled volumes of fluid—typically chemicals, additives, or reagents—into a process line or reaction chamber. Equipped with advanced features such as quick installation, easy operation, and automatic flow control, the system ensures both user convenience and dosing reliability. With multiple external control options and various operating modes (time-based, batch, proportional), it can easily adapt to complex process requirements.

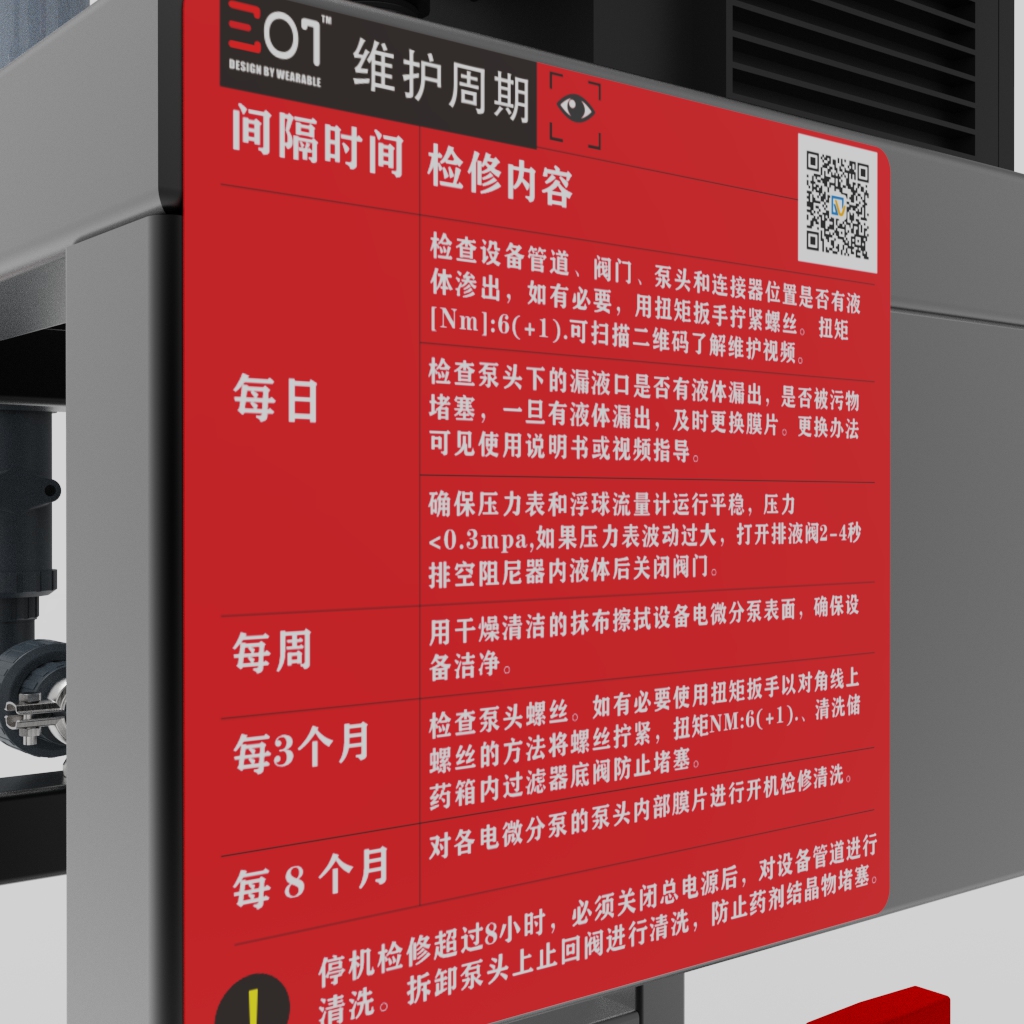

The system also includes condition monitoring and flow & pressure anomaly control, allowing operators to detect potential issues early, prevent process disruptions, and extend equipment lifespan.

Key Advantages

1. Quick Installation & Easy Operation

The modular design and intuitive interface allow for rapid deployment with minimal training. Whether integrated into a new setup or retrofitted into an existing line, installation is straightforward, minimizing system downtime.

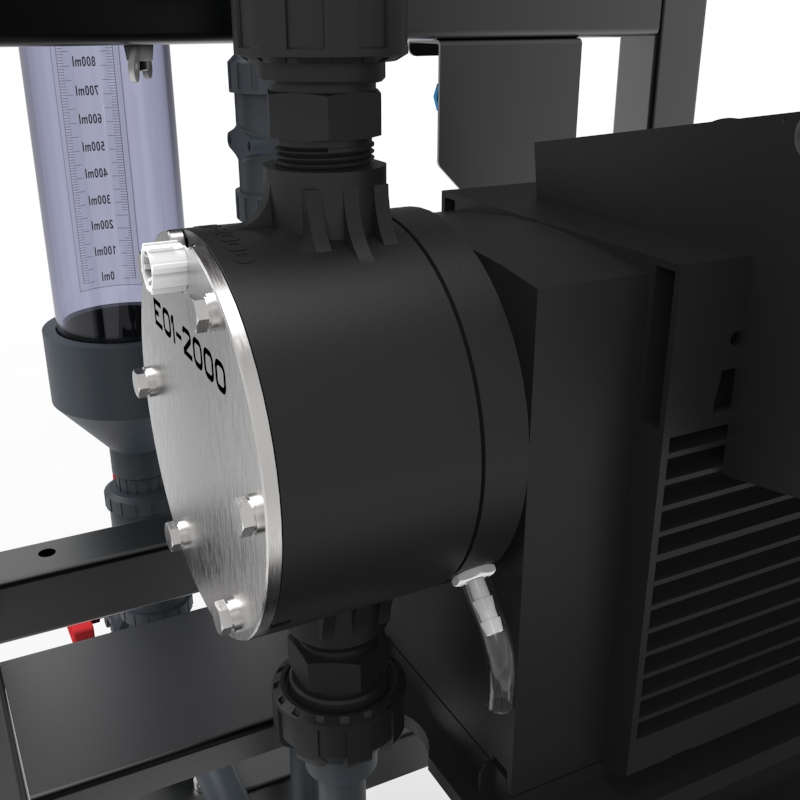

2. Precise Measurement & Stable Output

High-accuracy metering ensures precise dosing even at micro levels. This is essential for maintaining product quality, reducing chemical waste, and avoiding over- or under-dosing that could affect downstream processes.

3. Condition Monitoring for Predictive Maintenance

Built-in sensors and intelligent feedback systems constantly monitor flow rate, pressure levels, and system performance. Real-time alerts help operators identify and resolve problems before they escalate, reducing the risk of unplanned maintenance.

4. Multiple External Control Options

The high-precision digital dosing pump system is compatible with a variety of external control signals—analog, digital, or bus protocols—allowing for remote or centralized control through plant automation systems like SCADA or DCS.

5. Various Operating Modes for Flexible Applications

Whether the task requires continuous flow, intermittent batch dosing, or proportional injection based on system parameters, the dosing pump system can be configured to meet specific application demands.

6. Automatic Flow & Anomaly Control

To further ensure safety and accuracy, the system automatically adjusts to maintain target flow rates and quickly responds to any irregularities in pressure or delivery, safeguarding both the process and the equipment.

Typical Applications Across Industries

1. Sewage Treatment: Chemical Dosing in Water Plants

In water and wastewater treatment facilities, accurate dosing of chlorine, pH adjusters, and flocculants is critical. The dosing pump system ensures reliable, on-demand delivery of these chemicals to maintain safe and efficient treatment operations.

Benefit: Stable flow and real-time monitoring prevent chemical overdose and environmental discharge issues.

2. New Energy: Additive Dosing in Copper Foil Manufacturing

Battery-grade copper foil production requires exacting chemical control to achieve consistent quality and conductivity. The dosing system enables precise metering of brighteners, leveling agents, and other electrolytic additives during manufacturing.

Benefit: Precision dosing improves product quality and reduces material waste.

3. Bioenergy: Enzyme and Nutrient Injection

In biogas and bioethanol production, dosing enzymes at accurate concentrations supports microbial activity and energy yield. The system’s multiple dosing modes ensure that nutrients are introduced at the correct stage and volume.

Benefit: Optimized enzyme performance and improved energy conversion efficiency.

The dosing pump system stands out as a powerful, adaptable solution for industries requiring high-precision chemical metering. From municipal water treatment to new energy production, biotech, and automotive manufacturing, this system ensures safe, efficient, and automated control over critical fluid dosing operations.

With its intelligent features—such as automatic anomaly detection, flexible operation modes, and remote control compatibility—it not only improves process accuracy but also reduces operational costs and maintenance burdens. For manufacturers seeking long-term reliability, precision, and process optimization, the dosing pump system is an essential component in modern fluid handling strategies.