E01A 450-03 M1-1.4

Digital Dosing Pump Systems combine precision mechanics and advanced electronics to deliver accurate, continuous, pulse-free chemical dosing across industries like water treatment, chemical processing, new energy, and laboratories. Intelligent control systems enable manual or automated operation, supporting flow-proportional dosing, time-based batching, and integration with SCADA or PLC systems. Designed for reliability and accuracy, these pumps reduce errors, minimize chemical waste, and ensure operational transparency. Whether operating independently or as part of a smart dosing solution, they provide consistent performance and precise control for critical industrial dosing applications.

The dosing pump system is a state-of-the-art fluid handling solution designed to deliver accurate, reliable, and programmable chemical dosing across a broad range of industrial processes. Engineered to meet the demanding requirements of modern manufacturing and treatment facilities, this system offers an unmatched combination of precision measurement, operational flexibility, and advanced monitoring capabilities. Whether you need to dose corrosive acids in metallurgical plants, add scale inhibitors to cooling circuits, or feed masterbatch chemicals in automotive paint lines, this dosing pump system delivers consistent performance with ease.

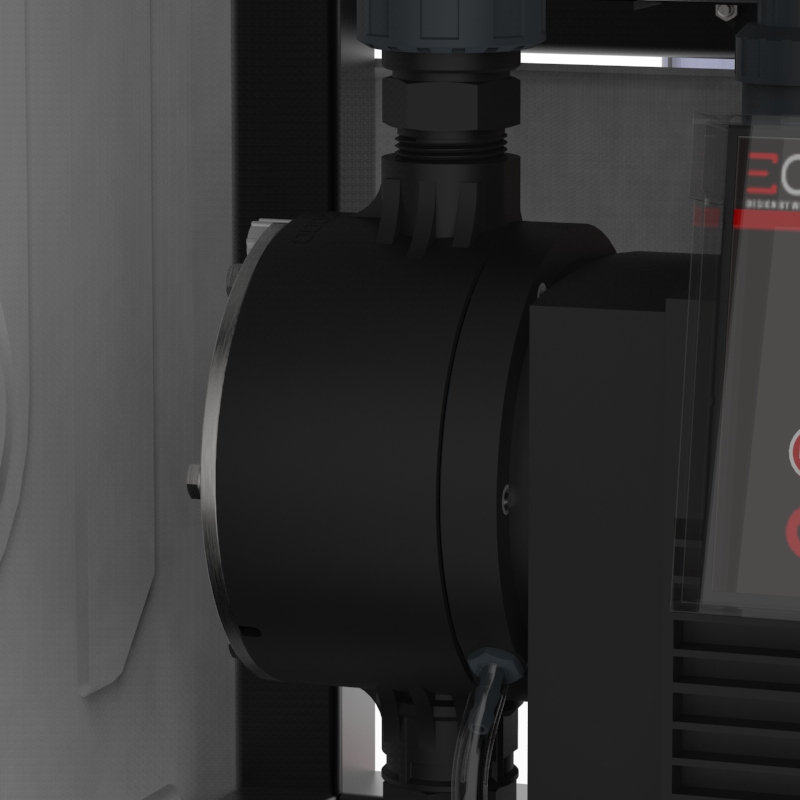

Designed for handling viscous, corrosive, or sensitive fluids, the Highn-Precisiodigital Dosing Pump System maintains stable and pulse-free dosing regardless of pressure fluctuations or feed variability. The system’s temperature-resistant construction and smooth internal surfaces protect delicate enzymes, catalysts, and additives from degradation during transfer, preserving their functional integrity.

Key Advantages

1. Quick Installation and Easy Operation

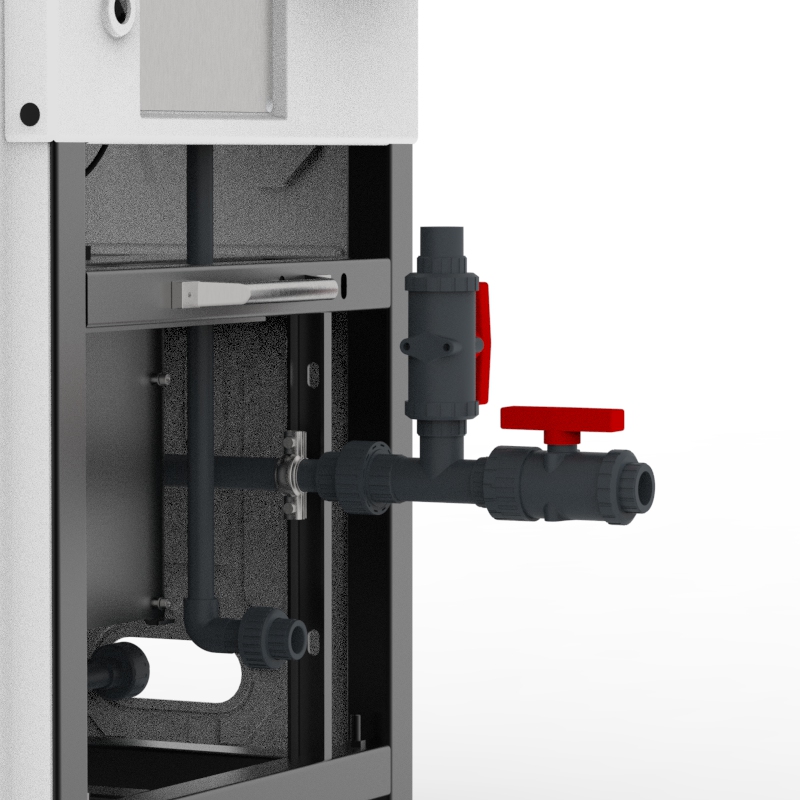

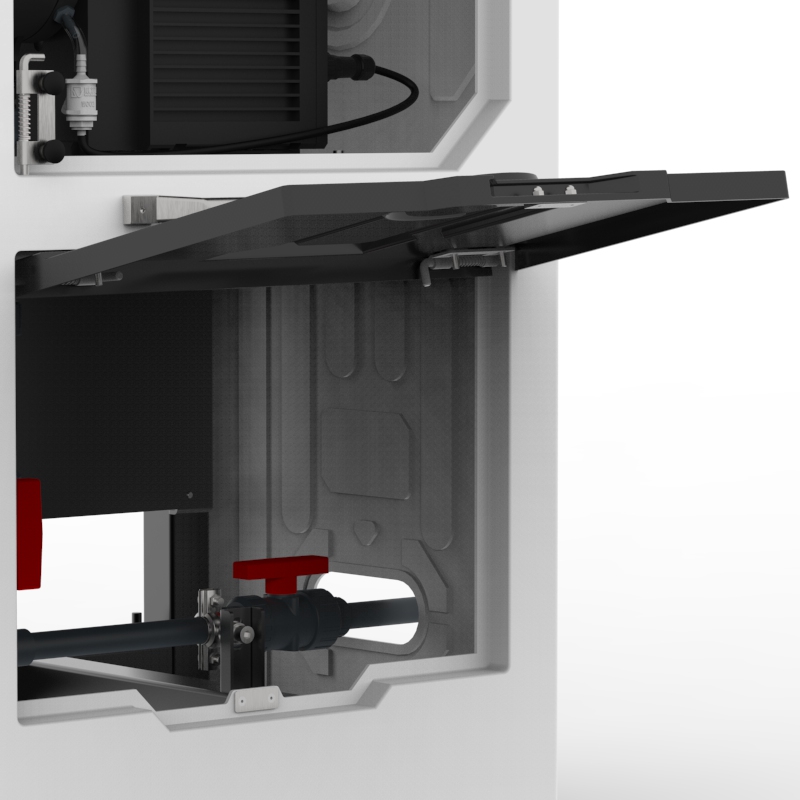

With a user-friendly design and modular components, the system can be installed rapidly with minimal disruption to existing operations. Its intuitive controls and digital interface enable easy configuration and operation by plant personnel without specialized training, reducing setup time and operational errors.

2. Precise Measurement and Automatic Flow Control

High-accuracy flow sensors and digital calibration ensure exact dosing volumes every cycle. The system automatically adjusts flow to compensate for changes in pressure or fluid viscosity, guaranteeing consistent delivery and optimizing chemical usage.

3. Condition Monitoring and Anomaly Detection

Equipped with real-time monitoring capabilities, the dosing pump continuously tracks flow rate, pressure, and pump performance. It immediately detects abnormalities such as blockages, leaks, or flow interruptions, alerting operators to potential issues and enabling proactive maintenance. This feature minimizes downtime and protects critical infrastructure.

4. Versatile Operating Modes

The system supports various dosing methods—continuous, proportional to flow or pressure, pulse dosing, and batch control—offering maximum flexibility for diverse applications. This adaptability ensures optimal chemical dosing tailored to specific process needs.

Application Highlights

1. Chemical and Smelting Acid Additives

In metallurgy and chemical manufacturing, accurate dosing of corrosive acids such as sulfuric or hydrochloric acid is critical. The dosing pump system’s corrosion-resistant materials and precise control enable safe and consistent acid injection, improving process stability and yield.

2. Industrial Cooling System Scale Inhibitor Addition

To prevent scaling and corrosion in industrial cooling circuits, continuous and precise dosing of scale inhibitors is necessary. The system maintains steady chemical delivery despite varying water flow and temperature, protecting equipment and reducing maintenance costs.

3. Metallic and Non-Metallic Beneficiation Chemicals Dosing

Mineral processing operations rely on exact dosing of flotation agents, pH modifiers, and dispersants. The pump system’s ability to handle abrasive slurries and adjust dosing rates dynamically helps optimize separation efficiency and resource use.

Specialized Features for Sensitive Fluids

The dosing pump system is also ideal for applications requiring gentle fluid handling. Its temperature-resistant design and smooth internal surfaces prevent damage to sensitive enzymes and bio-catalysts during transfer. Programmable dosing modes combined with optional real-time flow feedback allow dynamic adjustment of additive feed in bioreactors, digesters, or enzymatic pre-treatment tanks—supporting sustainable bioenergy production through efficient enzyme and nutrient dosing.

The dosing pump system represents a reliable, flexible, and technologically advanced solution for modern chemical dosing challenges. With rapid installation, intuitive operation, precise measurement, and robust monitoring features, it ensures optimized chemical use and improved process control across diverse industries. From metallurgical acid dosing to bioenergy enzyme injection and automotive paint formulation, this system delivers consistent, safe, and efficient fluid handling tailored to your process demands.