PAM+E01+M1

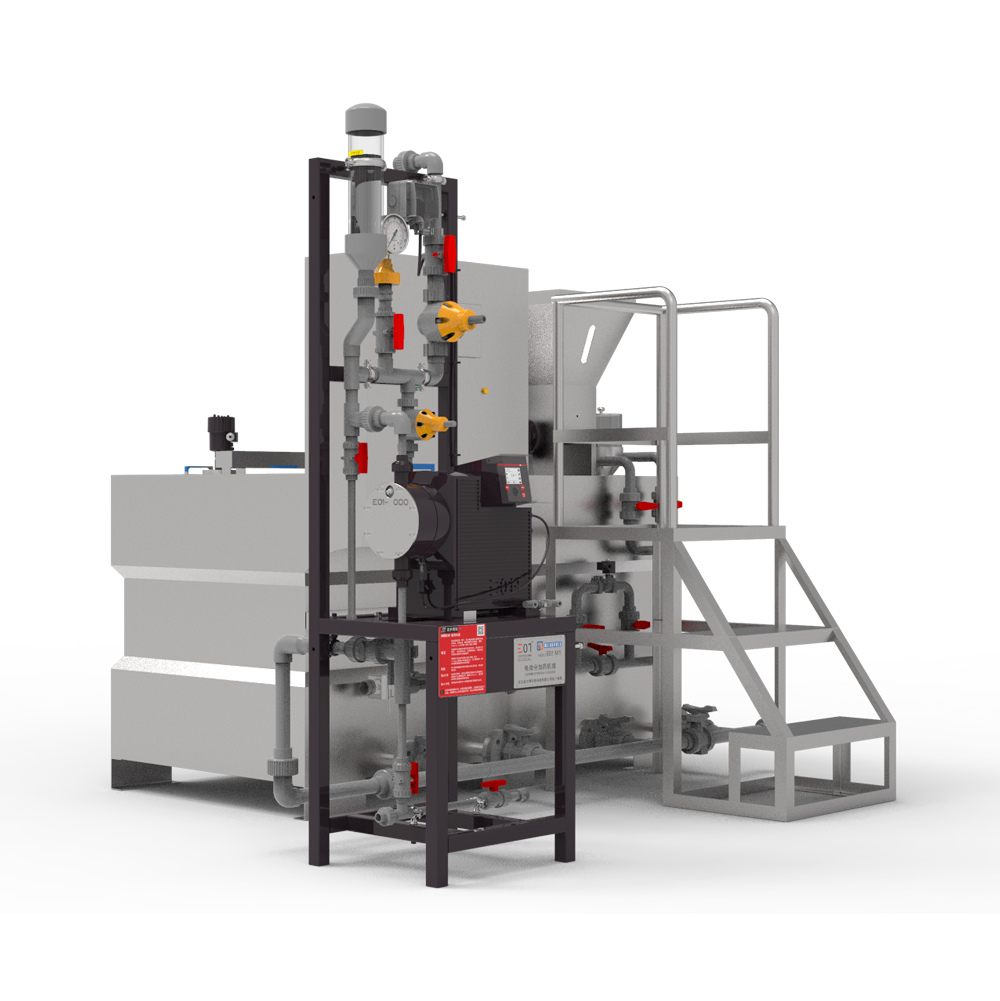

The Digital Dosing Pump is a diaphragm metering system driven by advanced algorithms and servo motors, delivering dosing accuracy within ±0.24%. Integrated YLC pressure sensors continuously monitor pipeline pressure, diaphragm condition, air bubbles, and blockages, triggering alarms or automatic air exhaustion when abnormalities occur. With flexible operating modes—including time-based, batch, and proportional dosing—the system adapts easily to applications in agriculture, food and beverage, pharmaceuticals, and energy, offering intelligent, fully automated chemical dosing.

Our digital dosing pump is diaphragm metering pump driven by advanced algorithms(Huawei chip) and servo motors,so the precision of our pump is very high,within the error of 0.24%. It is very intelligent and full-automatic.

In addition, our digital metering pumps are equipped with YLC sensors, it is a pressure sensor, continuously monitor pipeline pressure, diaphragm status, bubble,pipeline blockage to promise high precision.If any abnormal condition appear,YLC sensor can send alarm display on the screen.(If the air come into the pipeline,we can set automatic exhaustion)

Key Features

Smart, precise, and fully adaptable, the Durable Digital Dosing Pump is a powerful tool for modern fluid management.The Digital Dosing Pump is a precision-engineered solution designed to optimize chemical dosing with real-time Condition Monitoring and Multiple External Control Options. Whether operating in water treatment, food processing, or chemical manufacturing, this pump ensures consistent accuracy and adaptability.

Equipped with advanced sensors, the pump continuously monitors pipeline pressure, diaphragm status, air bubbles, and potential blockages. Its intelligent Condition Monitoring system alerts users to anomalies and protects against process interruptions. When paired with the AI algorithm module, the pump can independently perform PID control based on pH, fluid level, or concentration—without requiring an external PLC.

Multiple External Control Options make integration seamless across various systems. The pump supports analog input, digital signals, and communication protocols, allowing centralized or remote management via PLCs or SCADA platforms. Operators can switch between manual, time-based, batch, or proportional dosing modes to meet specific process demands.

To maintain optimal performance, users should verify sensor calibration and ensure compatibility with external control interfaces during setup.

Function

Manual mode:It is the basic function ,You can set any flow rate you want through the control button,milliliter per minute. (press the button to start set and press it to finish)

Concentration mode:you can automatically proportion the concentration of dosing chemcial though this mode. It has three choices,the difference is precision higher(PPM million grade)Now we can enter into first one,you can set the original concentration of your liquid and the dilute concentration you want.

Impulse mode:In this mode,we can connect outside impulse signal though the interface input3,adjust the flow rate according to the impulse signal;if we set 1 milliliter/impulse signal,and we set 1 hz,the flow rate is 60 milliliter per minute.

Impulse control:It is always used for impulse water meter,our pump can automatically adjust the flow rate according to the flow rate change of impulse water meter.

Batch mode:you can set how much liquids you need to convey at one time

Current mode:0-20MA(milliampere)4-20MA

Pause-work:For example,you can set the working hours to 240minutes,and interval for 30 minutes,it means the pump will work for 4 hours and stop work for 30 minutes,when interval time over it will restart work (Cycle and continuous operation)according to the working time and intervals you set.

Weekly mode:You can set the start working time,continue working time(duration)and also the flow rate.You can set the maximum 20 in a week,from Monday to Sunday.

ROC mode:connect external control and start or stop the pump though the external button,digital control box

Marginal Notes

[1] Test results based on an altitude below 100 meters, using pure water as the medium at a temperature of 20°C

[2] Pressure differential can be increased by adding a back pressure valve to the outlet

[3]Optional flow components with different materials are available to extend the temperature range og the medium.For more details,please consult the manufacturer.