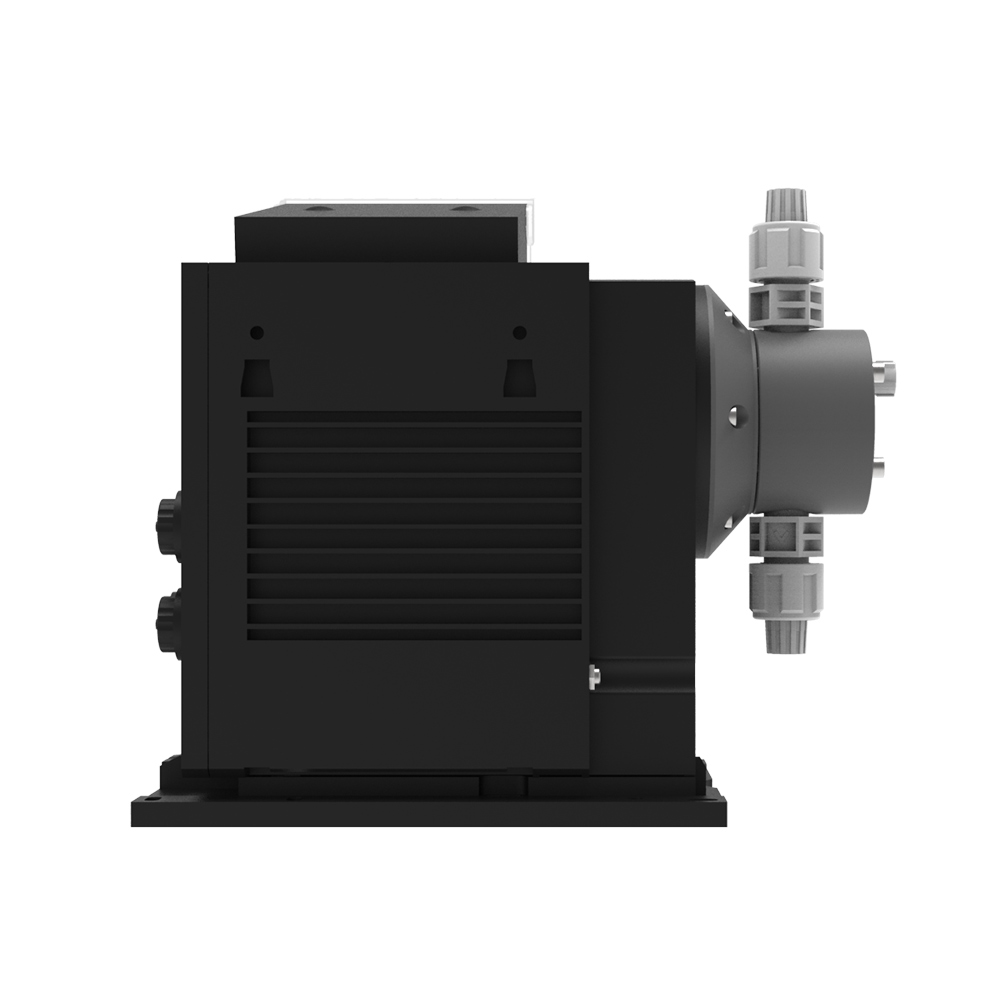

E01A 7.5-14

The Digital Dosing Pump is not just a pump—it’s a control unit that brings intelligence to chemical dosing. Designed to support both high-precision tasks and large-scale operations, it’s engineered for performance and longevity in demanding environments.What sets this system apart is its multi-mode flexibility. Users can choose between time-based, batch, or proportional dosing, depending on application needs. This makes it an ideal solution for sectors such as agriculture, food & beverage, pharmaceuticals, and energy.

Our Automatic flow control digital metering pump is a diaphragm-type dosing system designed for precise, stable, and intelligent fluid delivery. Powered by advanced control algorithms (utilizing a Huawei chip) and high-performance servo motors, the system delivers accurate dosing with an error margin as low as 0.24%. Its smart design enables fully automated operation, making it well-suited for applications that require continuous and controlled dosing performance.

To further enhance dosing reliability, each pump is equipped with a YLC pressure sensor. This sensor continuously monitors key parameters within the fluid pipeline—including pressure fluctuations, diaphragm movement, air bubble presence, and potential pipeline blockages. By tracking these variables in real time, the system helps maintain accurate and consistent dosing even under dynamic conditions.

Key Features

The Digital Dosing Pump is a smart and reliable solution designed with features like Automatic Flow Control and Flow & Pressure Anomaly Control, it ensures consistent performance even under varying process conditions.

The Automatic Flow Control function allows the pump to continuously adjust its dosing rate in response to real-time flow data. Whether facing changes in fluid viscosity, temperature, or system pressure, the pump adapts instantly to maintain dosing accuracy.

Complementing this, the Flow & Pressure Anomaly Control feature acts as a built-in safeguard. It monitors performance metrics and detects abnormal conditions like overpressure, line blockage, or unexpected flow fluctuations. When anomalies are detected, the system can automatically adjust performance, trigger alarms, or shut down to protect equipment and prevent process disruption.

Installation is quick, and the intuitive interface makes operation easy for all levels of users. However, to maximize performance, it’s essential to regularly check calibration, ensure sensor compatibility, and maintain clean fluid lines.

Function

Manual mode:It is the basic function ,You can set any flow rate you want through the control button,milliliter per minute. (press the button to start set and press it to finish)

Concentration mode:you can automatically proportion the concentration of dosing chemcial though this mode. It has three choices,the difference is precision higher(PPM million grade)Now we can enter into first one,you can set the original concentration of your liquid and the dilute concentration you want.

Impulse mode:In this mode,we can connect outside impulse signal though the interface input3,adjust the flow rate according to the impulse signal;if we set 1 milliliter/impulse signal,and we set 1 hz,the flow rate is 60 milliliter per minute.

Impulse control:It is always used for impulse water meter,our pump can automatically adjust the flow rate according to the flow rate change of impulse water meter.

Batch mode:you can set how much liquids you need to convey at one time

Current mode:0-20MA(milliampere)4-20MA

Pause-work:For example,you can set the working hours to 240minutes,and interval for 30 minutes,it means the pump will work for 4 hours and stop work for 30 minutes,when interval time over it will restart work (Cycle and continuous operation)according to the working time and intervals you set.

Weekly mode:You can set the start working time,continue working time(duration)and also the flow rate.You can set the maximum 20 in a week,from Monday to Sunday.

ROC mode:connect external control and start or stop the pump though the external button,digital control box

Marginal Notes

[1] Test results based on an altitude below 100 meters, using pure water as the medium at a temperature of 20°C

[2] Pressure differential can be increased by adding a back pressure valve to the outlet

[3]Optional flow components with different materials are available to extend the temperature range og the medium.For more details,please consult the manufacturer.