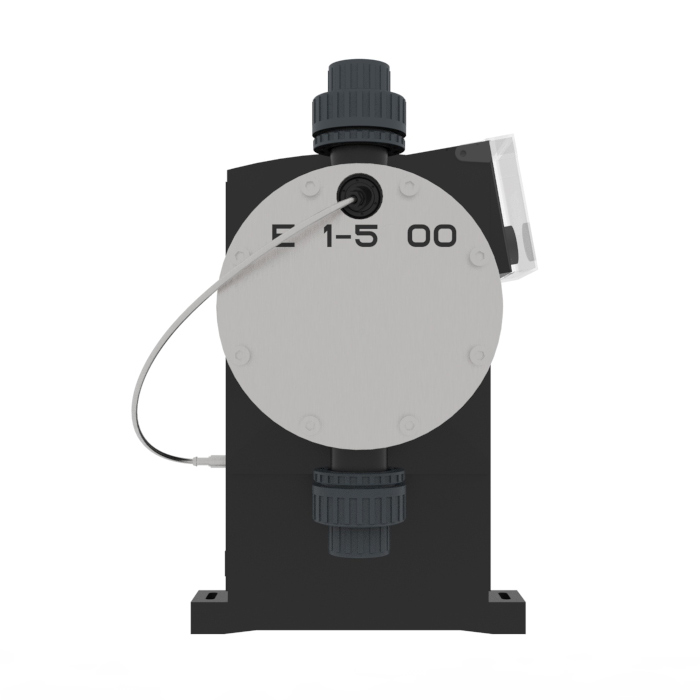

E01C 450-03

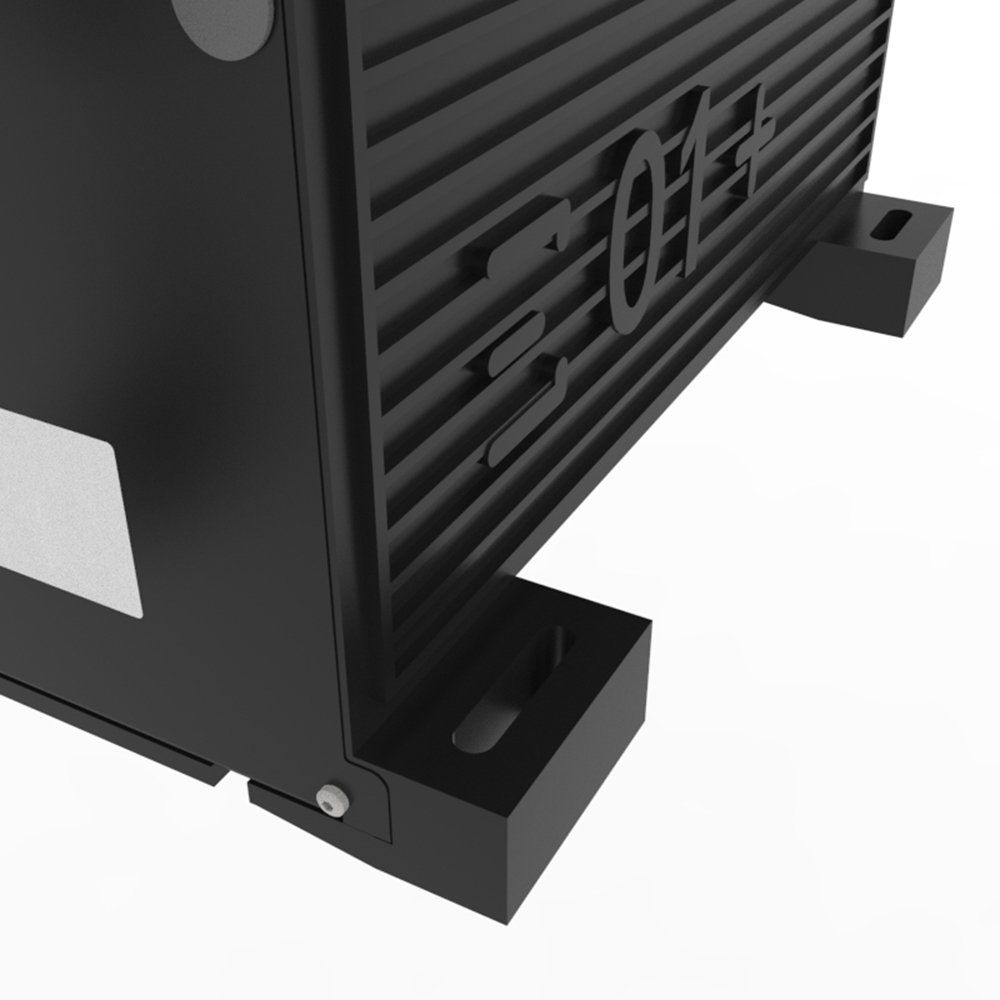

The Digital Dosing Pump functions as both a precision metering device and an intelligent control unit for chemical dosing. Driven by advanced algorithms and servo motors, it delivers high accuracy within ±0.24% and supports fully automatic operation. Integrated YLC pressure sensors continuously monitor pipeline pressure, diaphragm condition, air bubbles, and blockages, triggering real-time alarms and automatic exhaust when needed. Built for harsh chemicals and variable workloads, it ensures stable, low-maintenance performance in demanding industrial environments.

The Automatic flow control digital dosing pump is developed to address the practical requirements of modern industrial environments, offering a dependable and intelligent approach to accurate fluid dosing. Whether applied in chemical processing systems or routine operational tasks, this equipment supports precision, operational consistency, and user safety across various applications.

In addition to its technical functions, the system is designed with user experience in mind. The interface is easy to navigate, and users can select from multiple dosing modes while monitoring operational status in real time. Setup and calibration follow a straightforward process, and the use of wear-resistant components and built-in diagnostic tools contributes to simplified maintenance routines.

This Automatic flow control digital dosing pump offers a balanced and adaptable solution for fluid dosing tasks in industries such as water treatment, chemical production, and energy-related applications, helping operators maintain consistent process quality.

Easy Operation for Everyday Efficiency

One of the standout features of the Digital Dosing Pump is its easy operation. With a user-friendly interface and clear navigation menus, setup and adjustments can be completed in just a few steps. Whether adjusting dosage levels, setting operational intervals, or viewing system feedback, users benefit from simplified access to all core functions. The display panel is intuitive, reducing the learning curve and minimizing the risk of human error during operation.

Routine maintenance is also made easier through self-diagnostics and guided prompts. Operators can quickly identify issues, monitor performance, and make real-time adjustments without needing to refer to complex manuals or call for technical assistance. This plug-and-play convenience significantly reduces installation and training time, making the system suitable for fast-paced environments where downtime is costly.

Versatile Operation Modes for Varied Applications

In addition to ease of use, the pump offers various operating modes that can be tailored to meet specific process requirements. Whether the application requires continuous dosing, interval-based delivery, batch dosing, or flow-proportional injection, the Digital Dosing Pump can adapt accordingly. This makes it ideal for sectors like wastewater treatment, food processing, chemical manufacturing, and artificial cultivation—where different operational cycles are often necessary.

Each mode is easily selectable from the interface or remotely configured via control systems, offering flexibility in both standalone and integrated systems. The ability to fine-tune operational parameters in response to changing process conditions enhances accuracy and efficiency, while also supporting resource conservation and regulatory compliance.

Product Applications

The Digital Dosing Pump is widely used across various industries for precision chemical dosing, pH adjustment, disinfectant injection, and nutrient delivery. Common application areas include:

- Wastewater and water treatment plants

- Industrial and laboratory chemical processes

- Food and beverage production

- Aquaculture and agricultural fertilization systems

- Printing and dyeing industries

Key Usage Tips and Considerations

- Ensure correct calibration before use to maintain accuracy.

- Choose the right operation mode for each specific application to avoid under- or over-dosing.

- Perform regular maintenance checks, especially for wear-prone parts such as valves and diaphragms.

- Use compatible chemicals to prevent corrosion or pump damage.

- Monitor performance data if your system includes condition monitoring features for better long-term reliability.

By combining easy operation with adaptive functionality, the Digital Dosing Pump stands out as a practical and smart choice for industries that demand precision, flexibility, and efficiency in their fluid management systems.